26 July 2023

What Are the Risks with Jacky Bins?

Everything you Need to Know about Safe Storage and Handling using Jacky Bins

Are you wondering what risks are associated with using Jacky® Bins? Gearing up to make your purchase, but want to know all the ins and outs of these Big Boys before you sign on the dotted line?

We understand your concerns, and we’re here to acquaint you with the bad as well as the good. As one of our valued customers, we believe you have the right to know absolutely everything about our products before you buy.

Yes, there are risks associated with using Jacky® Bins. Like any other piece of equipment, they’re designed for a purpose, but if they’re misused they can pose serious safety risks. The science is pretty simple: use them correctly and they’ll work for you; abuse them or handle them incorrectly and you’ll pay for it.

So, let’s get down to business and look at some of the risks associated with Jacky® Bins:

1. Improper Handling Techniques

When you’re dealing with up to a tonne of product, your handling techniques have to be right: the reality is that accidents involving this sort of weight are extremely costly, and could even be fatal.

Use the Fork Pockets

Each Jacky® Bin frame is fitted with large, fully enclosed galvanized fork tyne pockets. Use these pockets when lifting; do not try to lift the bin from any other point of the frame.

No Slings Attached

Do not try to lift your Jacky® Bin using a sling.

Use Reliable Machinery

Only lift your Jacky® Bin with machinery that is reliable. Ensure that your lifting equipment is rated for the weight you are intending to lift.

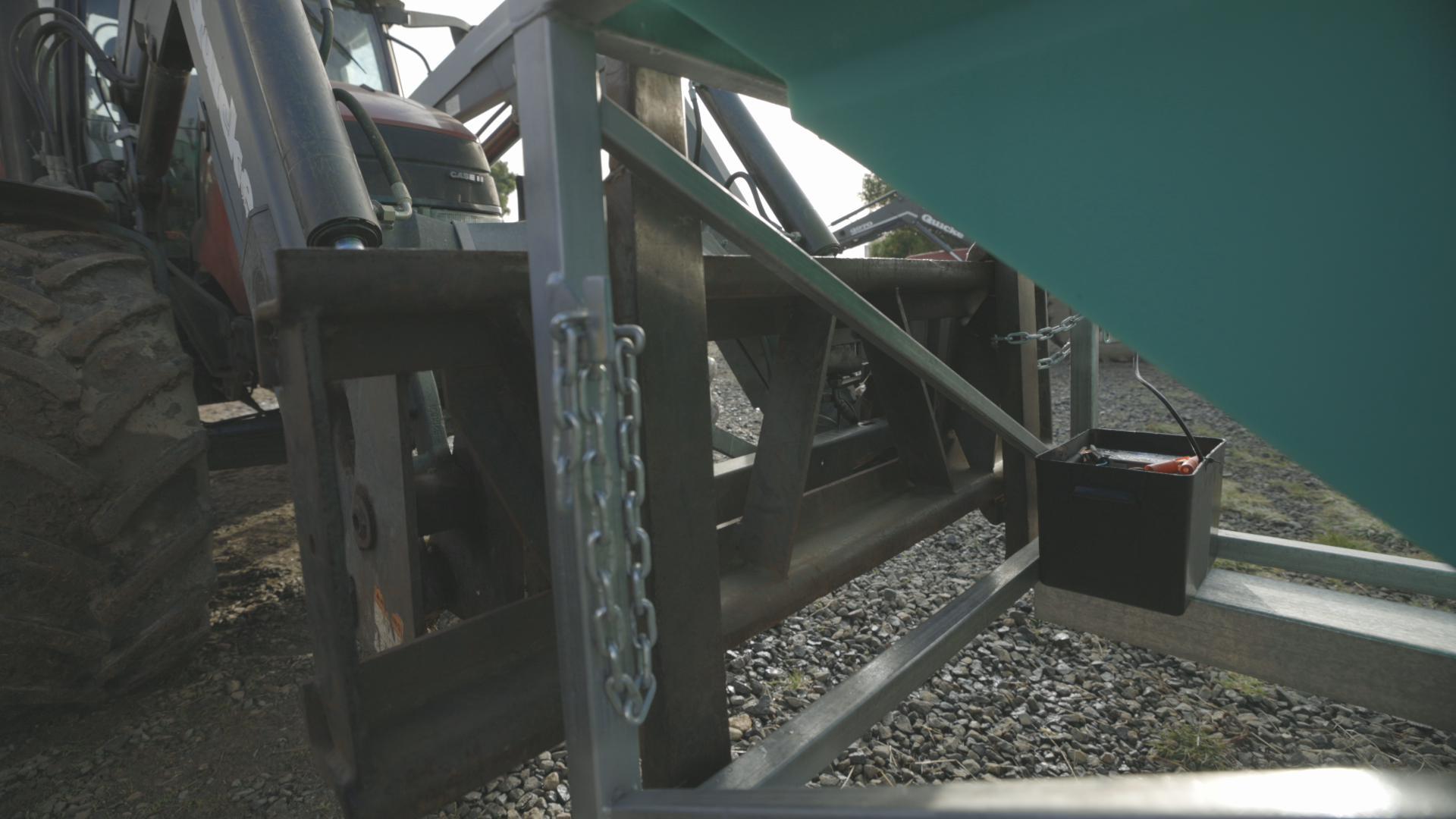

2. Failure to Chain Bin Back to Machine

Failure to chain your bin back to your machine may result in the bin sliding on the tynes during the lifting process. Each back leg of your Jacky® Bin frame has a safety chain and catch which is designed to attach to the headboard of your loader and prevent slipping.

3. Failure to Secure Load when Carting

Your bins must be properly secured during cartage. This includes securing the lids correctly to prevent them from blowing off during transport.

4. Overloading the Bins

Do not exceed the load capacity of your bins at any time. Overloading your Jacky® Bins can lead to structural failures which may result in harm to staff or machinery.

5. Chemical Contamination

In certain industries, Jacky® Bins are used to store and transport chemicals. If the hopper is not properly cleaned between uses, or if incompatible materials are stored together, cross-contamination can occur, leading to hazardous reactions or exposure risks for workers.

6. Unclean Working Areas

Jacky Bins are often moved around in storage areas, warehouses or production floors so it is important to ensure that all surfaces are clean and free of tripping and slipping hazards. Uneven surfaces, debris or inadequate lighting can contribute to accidents when moving, loading or unloading Jacky® Bins.

What are the Benefits of Using Jacky® Bins for Storage and Handling My Product?

There are several significant benefits of using Jacky® Bins for the storage and transport of materials for agriculture and industry, so keep reading:

Durability

Plastic is known for its durability. And the hopper of your Jacky® Bin is made from UV stabilized polymer which is resistant to impact, corrosion and moisture, making it suitable for a range of environments including warehouses, factories and outdoor settings. It can withstand rough handling, and transportation without compromising the structural integrity of the plastic.

All Jacky® Bin frames are made from Australian galvanized steel, and any metal accessories on the hopper are made from stainless steel.

Versatility

Jacky® Bins are available in a wide range of sizes, shapes and designs, offering versatile storage and handling solutions for a variety of products and applications. They can be fitted with bag splitters or various discharge systems to allow for easy filling and dispensing of product.

Hygiene-friendly

Jacky® Bin hoppers are made from easy-to-clean, food-grade polyethylene, making them ideal for applications with strict hygiene requirements such as food processing plants.

The non-porous interior surface of the hopper resists the absorption of liquids and prevents the growth of bacteria and mould.

The internal base design of the hopper ensures that there are no ledges or cavities where product can lodge, making the cleaning process simple and efficient.

Translucent Poly

The polymer used to mould the Jacky® Bin hopper is translucent, which means that the product level is easily visible through the bin wall.

Want to know more about the pros and cons of Jacky® Bins? Call us today on 1800 752 784 or send us a question right here and we’ll be in touch soon!